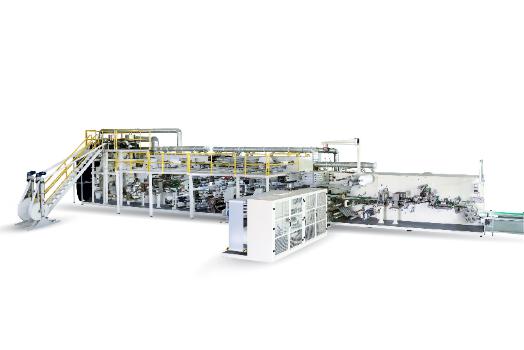

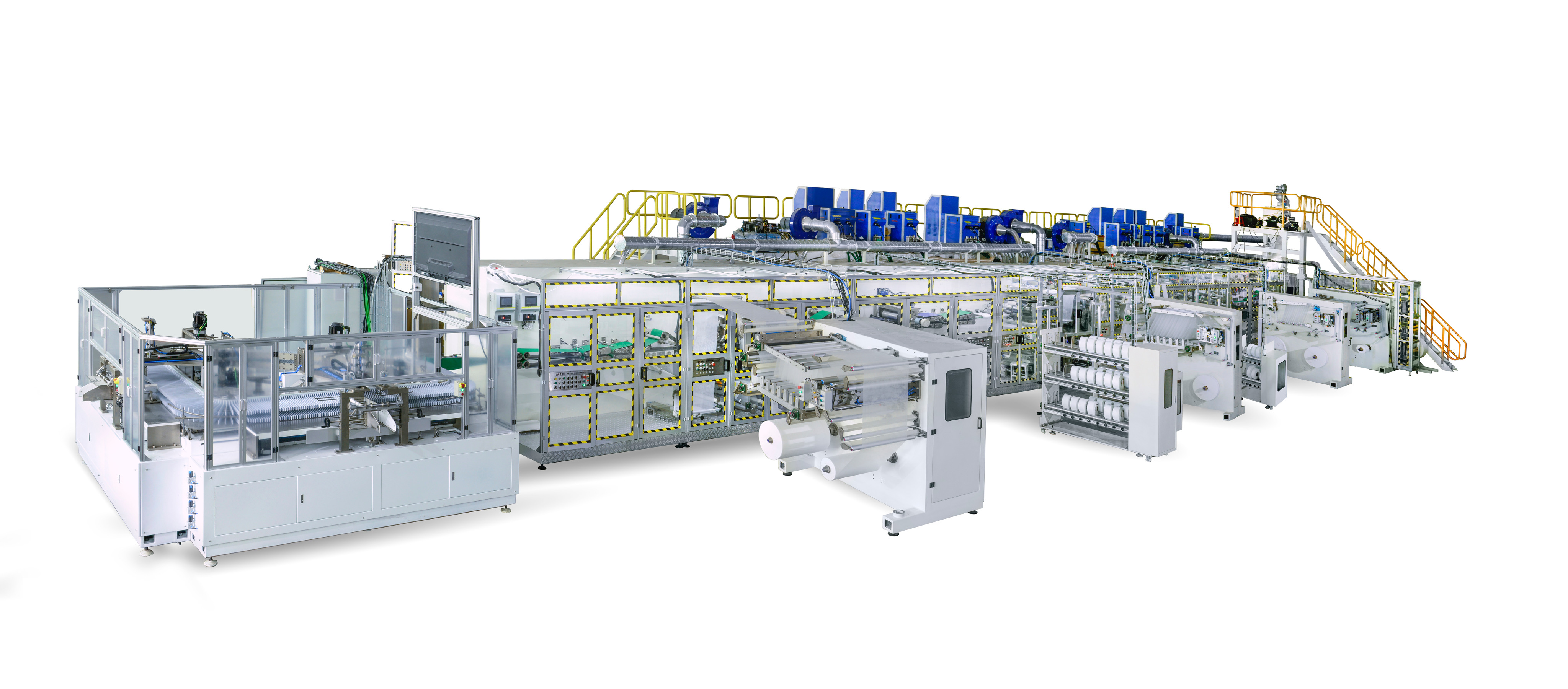

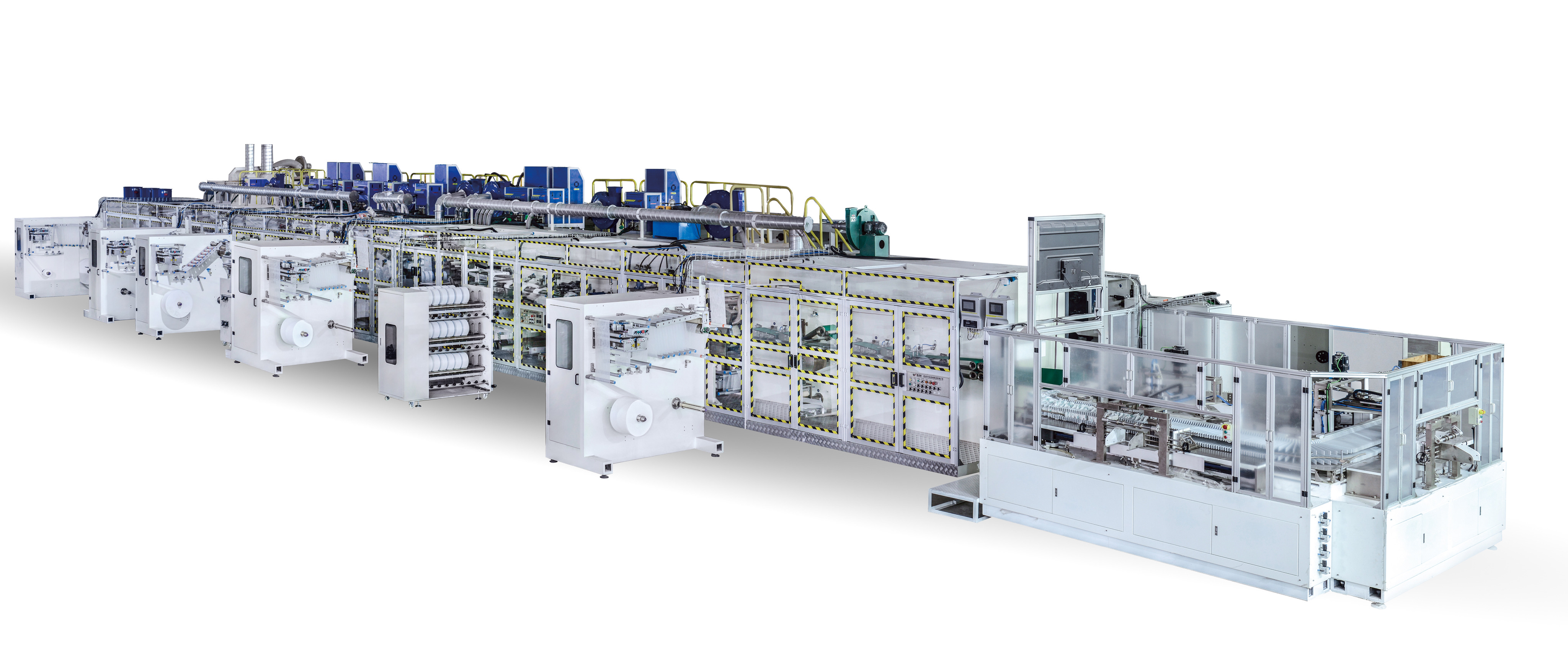

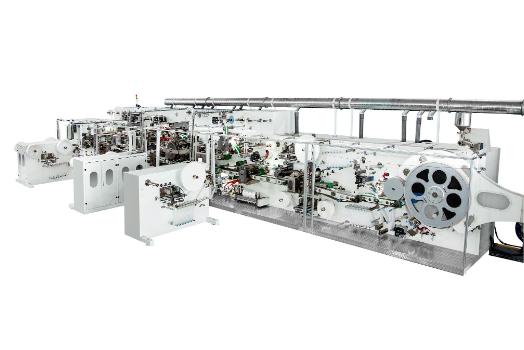

Full Servo I Shape Baby Diaper Making Machine

The Full Servo I Shape Baby Diaper Making Machine is a high-efficiency manufacturing solution for producing I-shaped baby diapers. This advanced full-servo system enhances automation, precision, and production stability, delivering quality products at a rapid pace. Engineered for high demand, this machine combines ease of use with top-grade production capabilities to meet diverse market needs.

Product Profile:

- Description: Designed for producing classic I-shaped baby diapers, this machine incorporates a fully automated servo system, ensuring precision and reducing manual intervention.

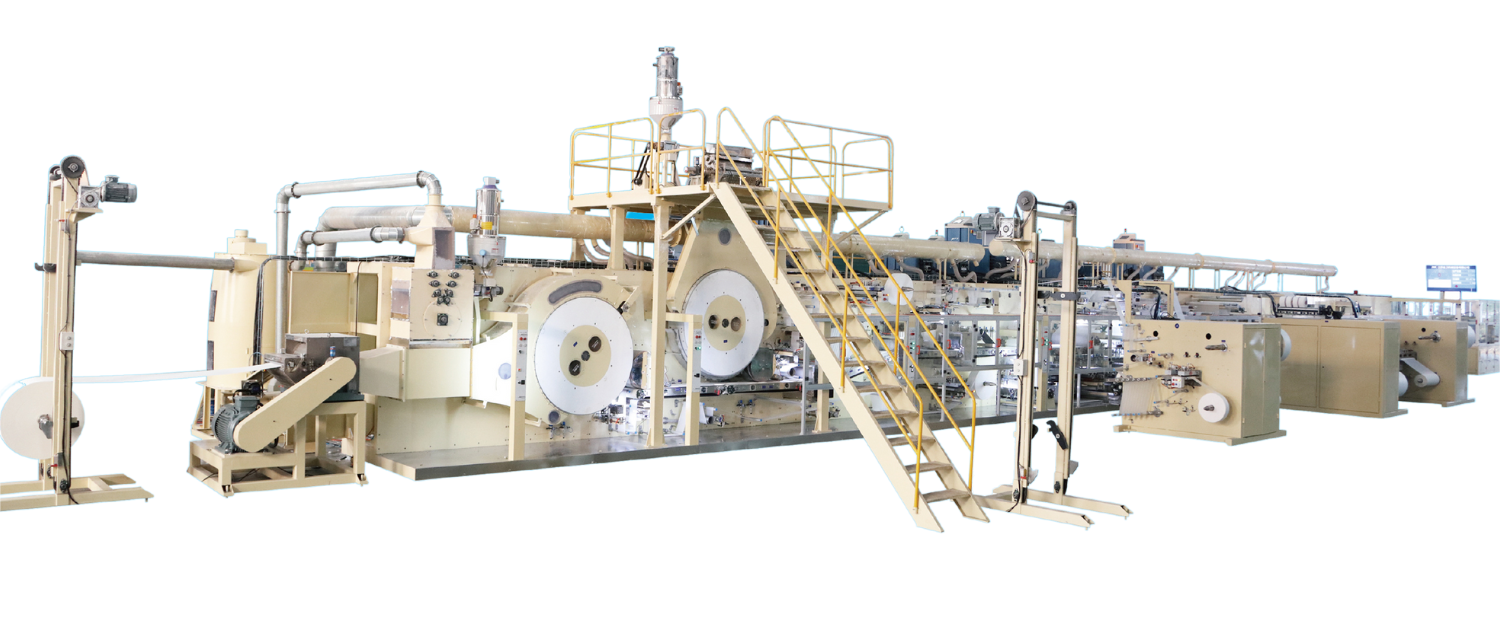

- Material Compatibility: Suitable for processing soft, breathable materials and highly absorbent cores, providing comfort and moisture retention for baby care.

Product Advantages:

- Full Servo Automation: The full-servo system provides high automation, enabling smooth and precise control across production stages, reducing the need for manual adjustments and enhancing efficiency.

- Consistent Quality: Ensures high product uniformity and quality due to precise component control, yielding a qualified rate of over 98%.

- Cost-Effective Production: Streamlines the production process to reduce operational costs, making it ideal for both cost-sensitive and quality-focused markets.

Applicable Market:

- Domestic Market: Tailored for markets requiring high-quality, affordable baby diapers with a comfortable fit.

- International Market: Well-suited for global distribution, addressing the high demand for reliable, efficient baby diaper manufacturing.

Machine Operation:

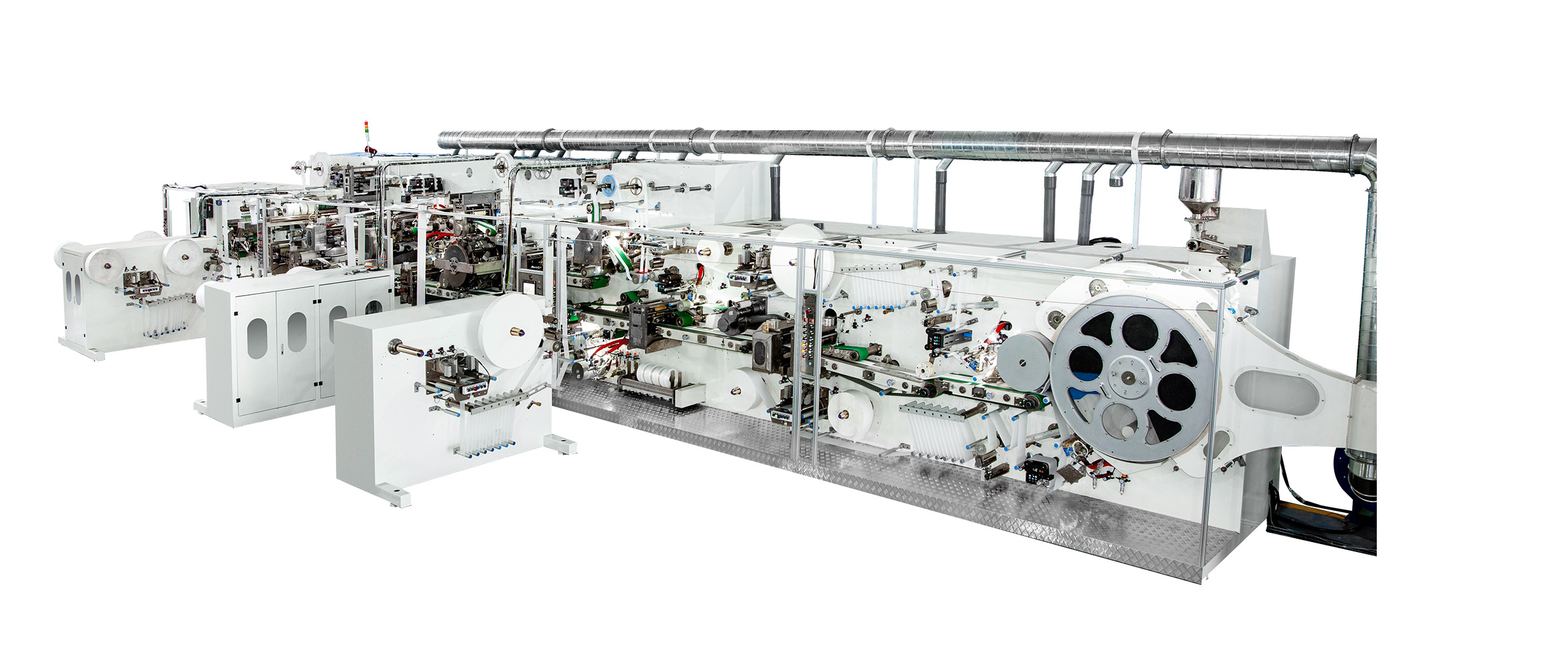

- User-Friendly Design: The machine features an intuitive touch screen interface, making it easy for operators to monitor and control the production process.

- Advanced Automation: With full servo control and a frequency converter, the machine achieves optimal efficiency with minimal labor requirements.

- High-Speed Performance: Capable of reaching stable speeds of 600 pieces per minute, ideal for high-volume production environments.

TECHNICAL PARAMETER

Design Speed | 700Pcs/M |

Stable Speed | 600Pcs/Min |

Power Supply | 380V 50Hz, Tri-phase |

Install Power | 300KW |

Product Size | M.L.XL.XXL |

Qualified Rate | ≥98% |

Machine Size | 45M×90M×4.5M(L×W×H) |

Weight | 108 Tons |

TECHNOLOGY FEATURES

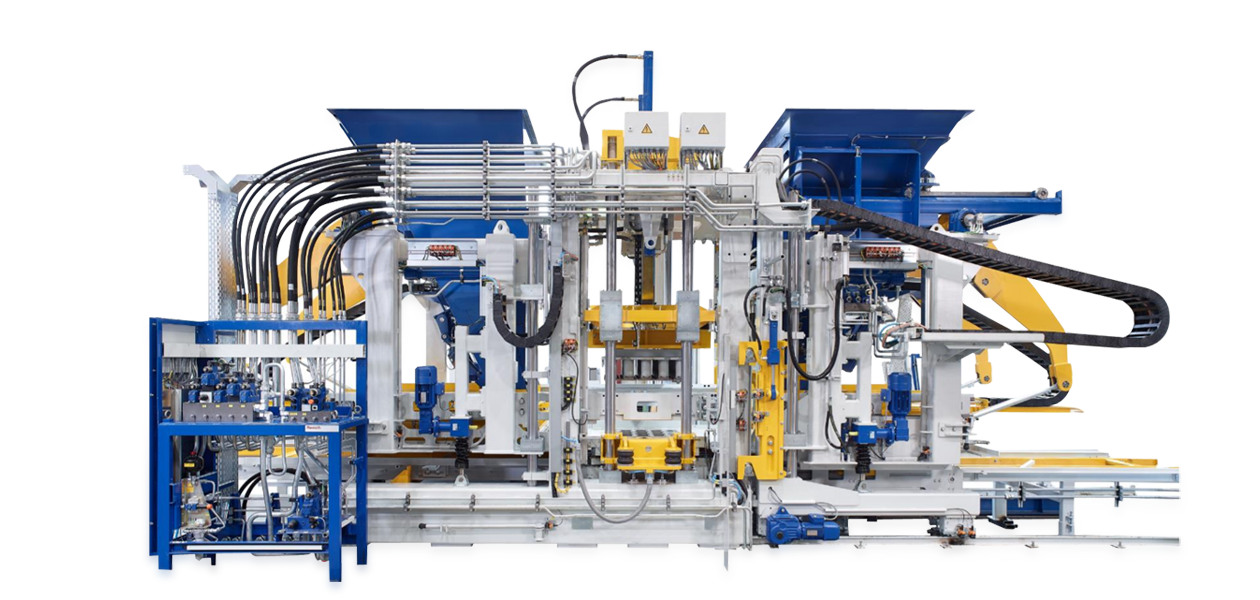

- Full-Servo Auto-Controlling System: Enhanced automation for seamless operation, allowing fine-tuned adjustments and reducing the need for manual intervention.

- Touch Screen Interface with PLC Control: Easy-to-use interface for efficient monitoring and adjustments.

- Precision Engineering: Main machine parts manufactured using CNC, ensuring high durability and precision.

- Automatic Web Guiding and Tension Control: Guarantees accurate alignment and material tension throughout the process.

- Comprehensive Production Tracking: Automatic calculation and recording of production data for improved process management.

- Quality Assurance System: Built-in quality control system automatically detects and rejects defective products.

- CE-Certified Design: Meets European safety standards for compliance and reliability.

- Compact, Efficient Layout: Offers a space-saving design with straightforward operation for streamlined workflow.

The Full Servo I Shape Baby Diaper Making Machine is engineered to deliver consistent quality, efficient operation, and superior automation. This machine is an optimal choice for companies looking to meet high production demands in both domestic and international markets, offering an excellent balance of performance, quality, and cost-efficiency.

Raw material list

No | Raw material | No | Raw material |

1 | Hydrophobic non woven ( leg cuff) | 8 | Leg spandex |

2 | Leak elastic | 9 | Pe film |

3 | Top sheet non woven | 10 | Waistband spandex |

4 | ADL | 11 | Waistband inner non woven |

5 | Upper tissue( or non woven) | 12 | Color tape |

6 | SAP+fluff pulp | 13 | Waistband outer non woven |

7 | Lower tissue( or non woven) | | |