Semi Servo Sanitary Pad Making Machine

Design Speed:1200Pcs/min

Stable Speed:1000Pcs/min

Install Power:300KW

Power Supply:200KW

Product Size:240*160mm,280*160mm (Customized)

Qualified Rate:≥98%

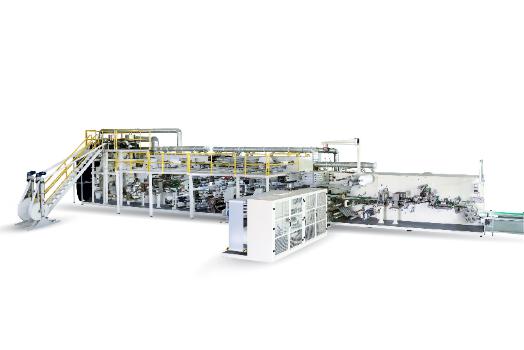

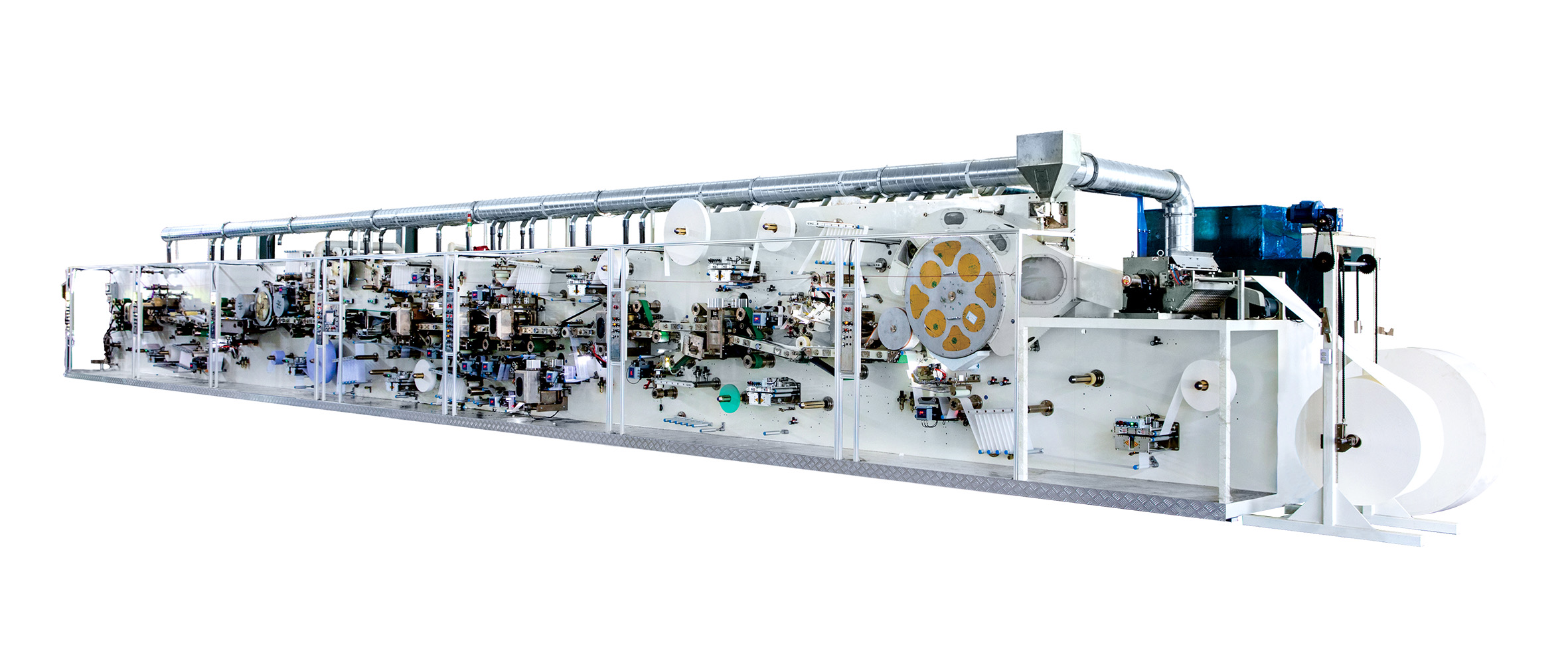

Machine Size:40M*11M*4M(L*W*H)

Weight:60Tons

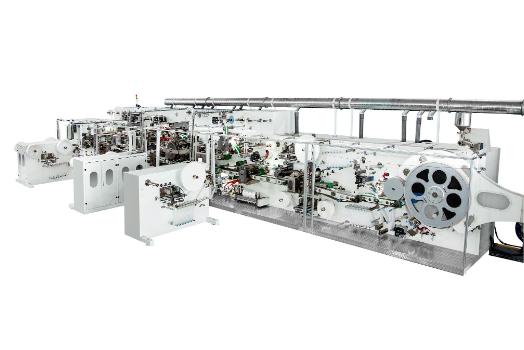

The Semi Servo Sanitary Pad Making Machine is a versatile, efficient solution for the production of sanitary pads tailored to various market needs. This machine combines semi-servo automation with user-friendly operation, allowing for high-speed production while ensuring product quality. It is an ideal choice for manufacturers looking to produce sanitary pads with precision and consistency.

Product Profile:

- Description: Specifically designed to manufacture sanitary pads in a variety of sizes, from 210mm to 420mm, catering to individual menstrual flow needs and preferences.

- Material Compatibility: Works seamlessly with absorbent, skin-safe materials, ensuring maximum comfort and reliable protection for the end user.

Product Advantages:

- Customizable Specifications: Capable of producing pads in multiple sizes, offering flexibility to meet varying demands, including options for daily use, overnight, and heavy flow.

- Durability and Reliability: Engineered for long-term use and high efficiency, this machine is designed to withstand continuous production with minimal maintenance.

Applicable Markets:

- Domestic Market: Satisfies the high demand for menstrual hygiene products in the local market, providing a dependable and affordable solution.

- International Markets: Meets the needs of global consumers with different product preferences, offering consistent and high-quality output suitable for export.

Machine Operation:

- Semi Servo Control System: Integrates semi-servo technology to provide a balance between automated functionality and manageable operation, minimizing labor while maintaining control.

- Efficient Production Process: Simplified design with fewer production stations, allowing for a streamlined workflow that reduces overhead and enhances productivity.

- Consistent High-Speed Output: Delivers a stable production speed of up to 1,000 pcs/min, ensuring timely output to meet market demands.

- Integrated Quality Assurance: Built-in quality control systems detect and reject any defective units, maintaining high standards in production.

TECHNICAL PARAMETER

Design Speed | 1200Pcs/min |

Stable Speed | 1000Pcs/min |

Install Power | 300KW |

Power Supply | 200KW |

Product Size | 240*160mm,280*160mm (Customized) |

Qualified Rate | ≥98% |

Machine Size | 40M*11M*4M(L*W*H) |

Weight | 60Tons |

TECHNOLOGY FEATURES

The Semi Servo Sanitary Pad Making Machine is a reliable and cost-effective solution for large-scale production of sanitary pads. With its balance of semi-servo control and automated features, it is designed to help manufacturers meet the demands of both domestic and international markets while upholding quality and efficiency.

Raw material list

No | Raw material | No | Raw material |

1 | Water repellent non-woven fabric | 7 | Wing release paper |

2 | Surface non-woven fabric | 8 | Easy to tear and paste |

3 | bibulous paper | 9 | Small capsule |

4 | Cotton core | 10 | Back release paper |

5 | toilet paper | 11 | Blue core |

6 | Bottom film non-woven fabric | | |