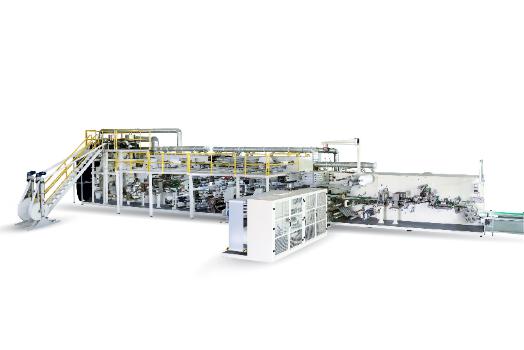

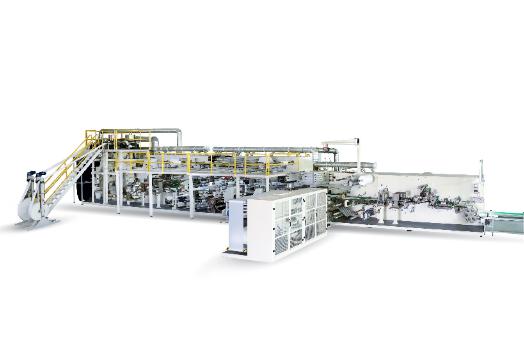

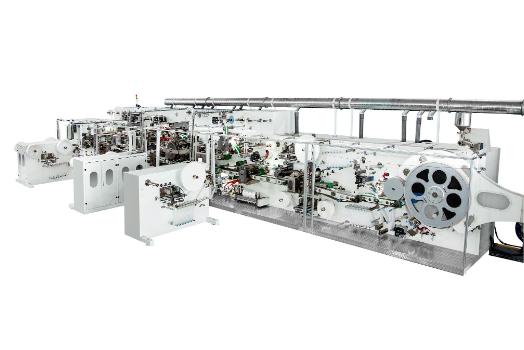

Full Automatic Adult Incontinent Pad Making Machine

Design Speed:350Pcs/Min

Stable Speed:300Pcs/Min

Power Supply:380V 50Hz, Tri-phase

Install Power:500KW

Product size:S.M. L

Qualified Rate:≥98%

Machine Size:45M×90M×45M(L×W×H)

Weight:108Tons

The Full Automatic Adult Incontinent Pad Making Machine is a high-efficiency solution engineered to produce adult incontinence pads with precision, comfort, and ease. This machine features advanced automation and streamlined production processes, ensuring reliable output for manufacturers targeting the adult care market.

Product Profile:

- Description: Designed specifically for creating adult incontinence pads, this machine caters to the needs of individuals with severe incontinence issues or mobility challenges requiring constant care.

- Material Compatibility: Utilizes absorbent, breathable materials to produce pads that ensure user comfort and dryness, even during prolonged use.

Product Advantages:

- High Comfort and Absorbency: The pads produced are optimized for comfort and secure absorbency, suitable for patients requiring intensive care.

- Efficient Production: Streamlined design and automation reduce labor complexity and improve production speeds, resulting in lower operating costs and higher output.

- Wide Market Relevance: Suited for hospitals, nursing homes, and in-home care settings, with applications in both domestic and international markets where adult care is a priority.

Applicable Market:

- Domestic Market: Targets the healthcare industry with products suitable for both private and institutional use, focusing on eldercare and adult incontinence solutions.

- Global Market: Designed for export, this machine meets the growing demand for affordable, quality incontinence care products worldwide, especially in regions with aging populations.

Machine Operation:

- User-Friendly Interface: Equipped with a touch screen controlled by PLC for easy interaction and streamlined monitoring.

- Minimal Labor Requirements: High automation reduces the need for manual intervention, making the operation less labor-intensive.

- Integrated Quality Control: Features a built-in quality assurance system that automatically detects and removes defective items, ensuring product quality and consistency.

- High-Speed Output: Capable of stable production speeds of 300 pcs/min, enabling manufacturers to meet high demand efficiently.

TECHNICAL PARAMETER

Design Speed | 350Pcs/Min |

Stable Speed | 300Pcs/Min |

Power Supply | 380V 50Hz, Tri-phase |

Install Power | 500KW |

Product size | S.M. L |

Qualified Rate | ≥98% |

Machine Size | 45M×90M×45M(L×W×H) |

Weight | 108Tons |

TECHNOLOGY FEATURES

The Full Automatic Adult Incontinent Pad Making Machine combines precision, speed, and reliability to meet the demands of modern adult care product manufacturers. With its advanced automation and quality control features, it is an ideal choice for high-volume production environments seeking dependable and efficient output.

Raw material list

No | Raw material | No | Raw material |

1 | Hydrophobic non woven ( leg cuff) | 6 | Pe film |

2 | Leak elastic | 7 | Side tape |

3 | Top sheet non woven | 8 | Frontal tape |

4 | Upper tissue( or non woven) | 9 | Leg spandex |

5 | SAP+fluff pulp | 10 | Lower tissue( or non woven) |