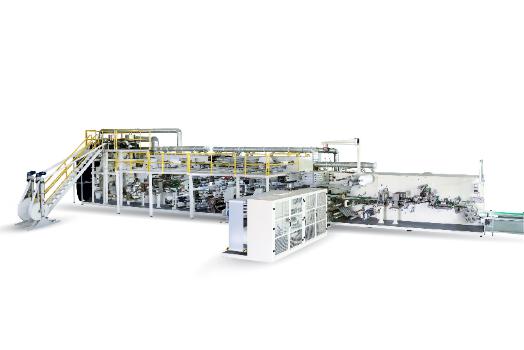

Full Frequency Convertor Control Adult Diaper Machine

Design Speed:350Pcs/Min

Stable Speed:300Pcs/Min

Power Supply:380V 50Hz, Tri-phase

Install Power:500KW

Product size:S.M. L

Qualified Rate:≥98%

Machine Size:45M×90M×45M(L×W×H)

Weight:108Tons

The Full Frequency Convertor Control Adult Diaper Machine is a state-of-the-art production solution, engineered for the efficient and precise manufacturing of adult diapers. Equipped with advanced automation, it is designed to meet the growing demand for high-quality incontinence products in both domestic and global markets, particularly for individuals needing extended care.

Product Profile:

- Description: This machine produces standard adult diapers ideal for individuals with severe incontinence or mobility challenges who require constant nursing care.

- Material Compatibility: Handles a variety of absorbent, breathable materials, ensuring that each diaper provides comfort and extended dryness for the user.

Product Advantages:

- Optimized for Comfort and Care: Diapers produced by this machine are designed for users requiring intensive, ongoing care, making them suitable for hospitals, nursing homes, and in-home care.

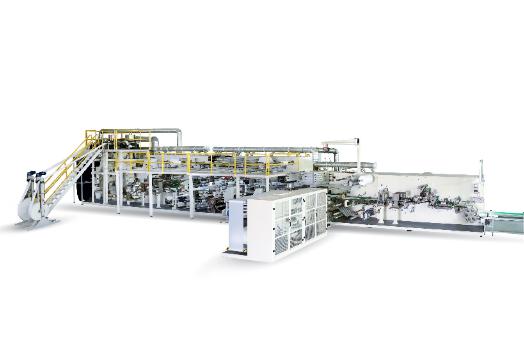

- Streamlined Production: A simplified machine structure with fewer stations minimizes production complexity and maximizes efficiency, resulting in cost-effective high-volume production.

- Wide Market Relevance: Essential for the healthcare sector, with applications in both private and institutional settings, and exportable to meet the growing global need for quality adult incontinence products.

Machine Operation:

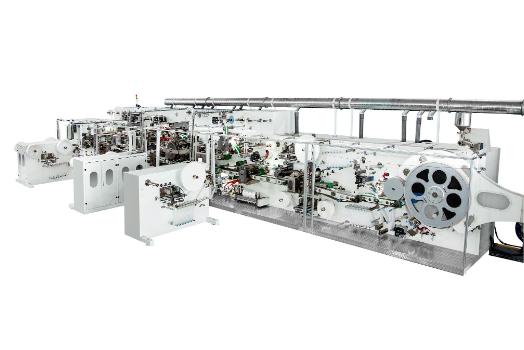

- Ease of Use: With a user-friendly, touch-screen PLC interface, the machine offers an intuitive operator experience, allowing for simple, accurate control.

- Labor Efficiency: Highly automated operation reduces the need for manual labor, enhancing productivity and lowering operational costs.

- Built-In Quality Control: The machine’s automated system identifies and rejects defective products, maintaining a consistent quality standard.

- High-Speed Production: Capable of reaching production speeds of up to 300 pcs/min, making it ideal for large-scale manufacturing needs.

TECHNICAL PARAMETER

Design Speed | 350Pcs/Min |

Stable Speed | 300Pcs/Min |

Power Supply | 380V 50Hz, Tri-phase |

Install Power | 500KW |

Product size | S.M. L |

Qualified Rate | ≥98% |

Machine Size | 45M×90M×45M(L×W×H) |

Weight | 108Tons |

TECHNOLOGY FEATURES

The Full Frequency Convertor Control Adult Diaper Machine is an ideal choice for manufacturers seeking a dependable, high-speed solution for the production of adult incontinence products. With its advanced automation, quality control, and high production speeds, this machine is engineered to support large-scale production with consistent, high-quality output.

Raw material list

No | Raw material | No | Raw material |

1 | Hydrophobic non woven ( leg cuff) | 6 | Pe film |

2 | Leak elastic | 7 | Side tape |

3 | Top sheet non woven | 8 | Frontal tape |

4 | Upper tissue( or non woven) | 9 | Leg spandex |

5 | SAP+fluff pulp | 10 | Lower tissue( or non woven) |