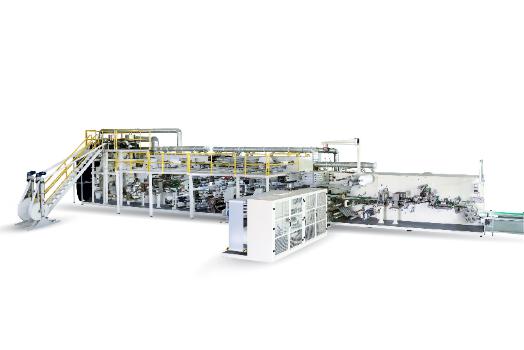

Full Servo Disposable Pet Pad Making Machine

The Full Servo Disposable Pet Pad Making Machine offers a cutting-edge solution for high-efficiency production of pet pads and underpads. Utilizing advanced full servo technology, this machine is engineered to meet diverse production needs, from economical to premium-quality pet pads. With customizable size and absorbent material options, this machine delivers flexibility, precision, and unmatched reliability, making it ideal for businesses focused on quality, speed, and consistent output.

Product Profile:

- Versatile Output: Capable of producing pet pads of various grades, from standard to high-quality, as well as custom underpads, fulfilling multiple market requirements.

- Full Servo Control: Equipped with intelligent servo motors, the machine offers accurate control over production speeds and quality, ensuring high-precision output.

Product Advantages:

- Adjustable Specifications: Supports customized pad dimensions, from length to width, with adjustable quantities of Super Absorbent Polymer (SAP) and fluff pulp for tailored absorbency.

- High Intelligence & Efficiency: With up to 30 servo motors and advanced automation, the machine maintains consistent quality without requiring frequent manual adjustments, reducing downtime and labor costs.

Applications:

- Wide Market Scope: Ideal for manufacturing pet training pads, hospital pads, baby and adult incontinence pads, as well as disposable pads for healthcare and veterinary uses.

- Global Applicability: Designed to meet international standards, making it suitable for both local markets and export to global markets where pet care products and underpads are in demand.

Machine Operation:

- User-Friendly Automation: A full PLC control system with a touch screen enables easy monitoring and adjustment, making operation simple and efficient.

- High-Speed Output: Capable of achieving stable speeds up to 230 pads per minute, with a designed maximum speed of 300 pads per minute.

- Quality Assurance System: Integrated automatic quality control features detect and reject defective pads, maintaining a high production qualification rate of ≥ 97%.

Technical Parameters:

- Production Speed: Stable speed of 230 pcs/min, with a maximum design speed of 300 pcs/min

- Installed Power: 200KW

- Air Pressure Range: 0.6–0.8Mpa

- Width & Length of Pads: Adjustable from 800mm to 1200mm (width) and 800mm to 3000mm (length)

- Material Structure: Includes a top sheet of nonwoven fabric, a cotton and SAP absorbent core, and a PE waterproof back sheet for optimal performance.

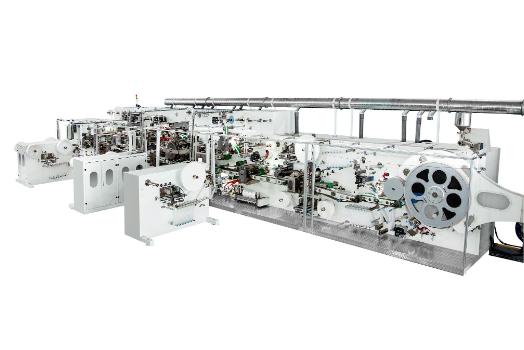

Technology Features:

- Advanced Full Servo System: Provides precise control over all operational functions, delivering higher speeds, accuracy, and efficiency compared to semi-servo models.

- Touch-Screen PLC Interface: The user-friendly touch screen enables easy adjustments, production monitoring, and operation control.

- Automated SAP Integration: Automated control over SAP distribution in the absorbent core, allowing customization of thickness and absorbency.

- Automatic Material Handling: Features automated splicing, tension control, and phase adjustment systems, reducing the need for manual intervention.

- Auto Reject System: Automatically detects and removes defective pads to maintain consistent product quality.

- European CE Compliance: Designed to meet CE standards, ensuring safe and reliable operation aligned with global manufacturing practices.

Applications of Full Servo Disposable Pet Pad Making Machine:

- Pet Training Pads: Perfect for manufacturing absorbent pads tailored to pet training needs.

- Medical Pads: Suitable for healthcare applications, including incontinence products for hospitals and senior care facilities.

- Baby and Adult Care Products: Capable of producing versatile disposable pads, including baby diapers and pads for elderly care.

- Hospital and Veterinary Use: Provides durable and reliable pads for clinical settings, meeting sanitary requirements.

The Full Servo Disposable Pet Pad Making Machine is a premier choice for manufacturers seeking efficiency, quality, and versatility. With its advanced automation and precise control, this machine is tailored to meet high-demand production requirements while maintaining exceptional product quality and operational ease.