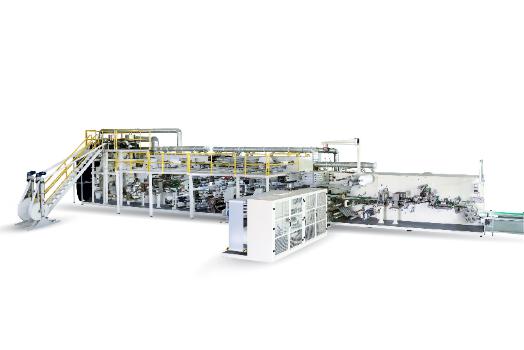

Full Servo Underpad Making Machine

The Full Servo Underpad Making Machine is an advanced manufacturing solution designed to produce a wide range of disposable underpads and pet pads, from regular to high-grade varieties. Engineered with full servo technology, this machine ensures superior efficiency, precision, and control, making it an ideal choice for companies seeking high-output, customizable production. With options to adjust the size, absorbent materials, and layer configurations, this machine meets diverse industry needs in healthcare, pet care, and personal care applications.

Key Features:

- Customizable Production: Tailor the machine settings to produce underpads and pet pads of various types, including economical and premium options. Adjust pad dimensions, absorbent content, and material layering for unique product requirements.

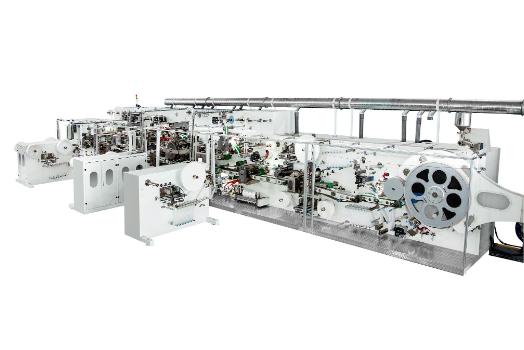

- Full Servo Technology: Equipped with high-precision servo motors, this machine offers unparalleled operational accuracy, speed control, and energy efficiency. The absence of gearboxes reduces downtime and maintenance costs while improving long-term durability.

- Advanced Control System: With integrated PLC programming and a touch-screen interface, the machine allows operators to monitor and adjust production parameters in real-time, ensuring consistent product quality and ease of use.

- Automated Features: Enjoy smooth, uninterrupted production with automated systems for material feeding, splicing, and waste rejection. The auto-tension control and phase adjustment maintain optimal performance without manual intervention.

Performance Specifications:

- Production Speed: Stable output at 230 pieces per minute, customizable up to a maximum design speed of 300 pieces per minute.

- Dimensional Range: Pad widths from 800 to 1200mm and lengths from 800 to 3000mm, offering flexibility for various product requirements.

- High Product Accuracy: Minimal weight deviation at ±5%, with a qualification rate of ≥ 97%.

- SAP and Pulp Control: The machine’s design allows for precise adjustment of SAP and fluff pulp quantities, enabling optimal absorbency for each product.

- Power Requirements: Operating power capacity of approximately 200KW, with air pressure settings between 0.6 and 0.8Mpa to maintain stability and consistency.

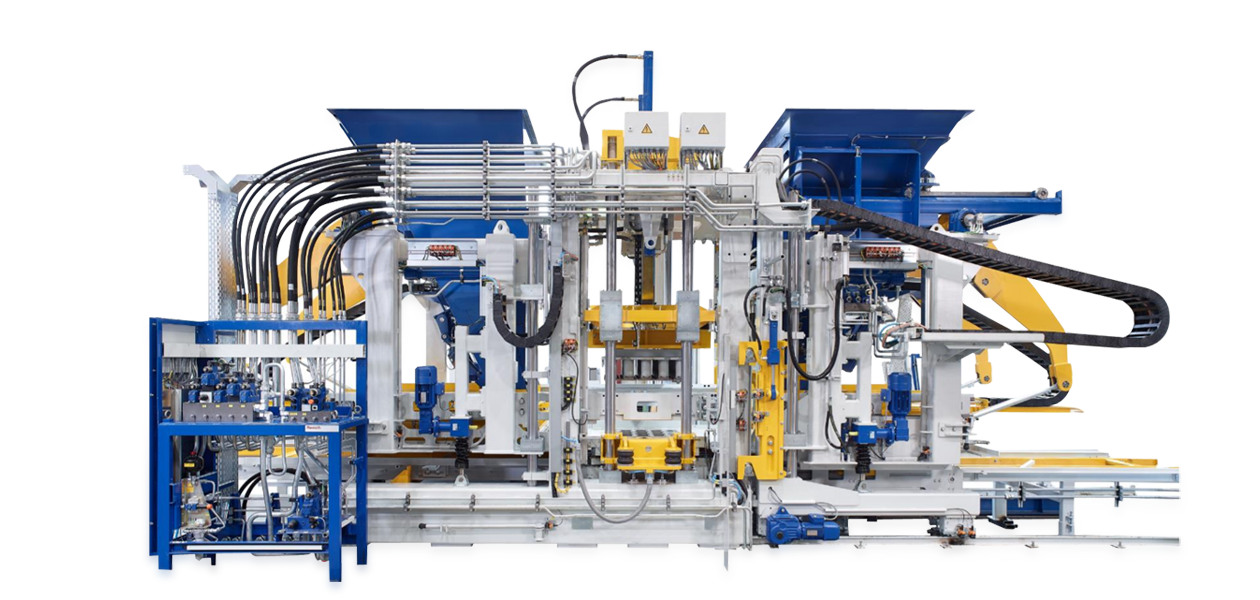

Structural Components:

- Top-Grade Materials: Includes a durable nonwoven top sheet, middle layers of cotton and SAP for enhanced absorbency, and a PE back sheet for added protection.

- Core Technology: The pulp collection box evenly distributes absorbent material, while servo-driven cutters and SAP feeding systems maintain precision throughout each production stage.

Applications:

The Full Servo Underpad Making Machine is versatile, catering to multiple sectors:

- Medical and Healthcare: Ideal for hospital surgical underpads and incontinence care.

- Pet Care: Produces puppy training pads and pet pads for household and veterinary use.

- Personal Care: Capable of creating baby diapers, sanitary napkins, and other hygiene products.

Why Choose Our Full Servo Underpad Making Machine?

SQ’s Full Servo Underpad Making Machine is a robust solution for businesses aiming to scale production without compromising on quality. Backed by ISO certification and a commitment to innovation, SQ’s machines are trusted for their reliability, durability, and exceptional performance across a variety of production demands. Our team provides full technical support to ensure a smooth installation and ongoing operation, making this machine a valuable asset for any disposable pad manufacturing facility.