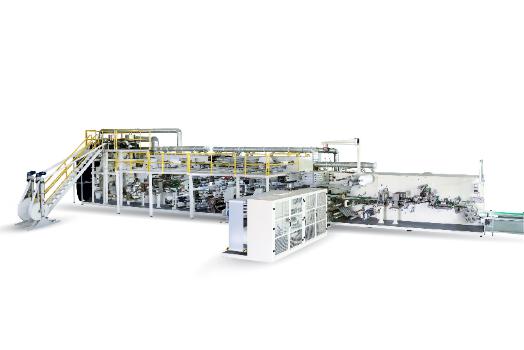

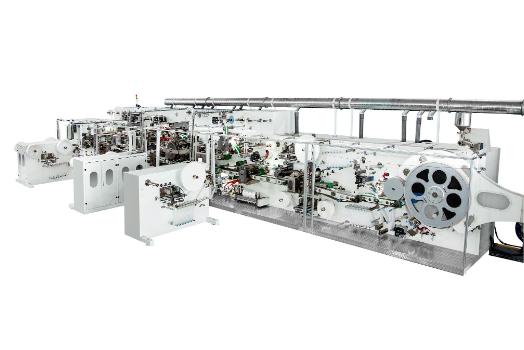

Semi Servo Underpad Making Machine

The Semi Servo Underpad Making Machine offers a streamlined and economical solution for manufacturing underpads of various sizes and specifications. Designed with a semi-servo system, it provides precise control, reliable performance, and efficiency. This machine is an ideal choice for manufacturers seeking high-quality output and cost-effective operations in the production of disposable underpads for healthcare, pet care, and other applications.

Key Features:

- Customizable Pad Dimensions: Easily adjust the width and length to produce underpads tailored to specific requirements, making it versatile for various markets, including medical, personal care, and pet care.

- Semi-Servo Technology: The semi-servo system ensures stability and high precision during operation, reducing power consumption while maintaining consistent pad quality.

- SAP & Pulp Adjustability: Control the amount of SAP (super absorbent polymer) and fluff pulp to achieve the desired absorbency levels, allowing customization for different applications and absorbency needs.

- Automated Functions: Integrated with systems for automatic feeding, cutting, and splicing of raw materials, the machine minimizes manual intervention, boosting productivity and reducing labor costs.

- User-Friendly Interface: Equipped with a PLC touch screen interface, this machine allows operators to adjust settings easily and monitor production in real time, enhancing efficiency and ease of operation.

Performance Specifications:

- Production Speed: Capable of producing up to 200 pieces per minute, with settings that allow for adjusting speed to meet various production demands.

- Adjustable Dimensions: Produces underpads with widths ranging from 300 to 800mm and lengths from 400 to 1500mm, covering a wide range of product specifications.

- Power and Air Pressure Requirements: Operating at 150KW with an air pressure requirement of 0.6-0.8 Mpa, the machine is optimized for stable and energy-efficient performance.

- Quality Control Precision: Maintains a product weight deviation of ±5%, ensuring consistent pad thickness and absorbency in each production batch.

Structural Components:

- Multi-Layer Construction: Each underpad produced features a soft nonwoven top layer, an absorbent middle core made of SAP and fluff pulp, and a leak-resistant PE back sheet, ensuring comfort and reliability for end users.

- Accurate Feeding and Cutting: The semi-servo system provides precise regulation over the feeding and cutting processes, resulting in uniformly sized pads with consistent absorbency.

Applications:

The Semi Servo Underpad Making Machine is engineered for producing a variety of underpads suitable for:

- Healthcare and Hospitals: Underpads for patient care, incontinence, and surgery.

- Pet Care: Disposable pet pads ideal for training and hygiene.

- Home Care: Absorbent pads for elderly or bedridden individuals requiring additional care.

Why Choose SQ’s Semi Servo Underpad Making Machine?

As a trusted provider of underpad production equipment, SQ delivers solutions that emphasize durability, efficiency, and customization. The Semi Servo Underpad Making Machine is engineered for long-lasting performance and versatility, helping manufacturers meet diverse product specifications and industry demands. SQ offers full technical support and quick installation, ensuring a smooth operational setup. Choose SQ for reliable, efficient, and tailored solutions in underpad manufacturing.